Thermal growth, equipment movement, vibration or pressure pulsation may generate movement in a piping system. When this movement is not absorbed by the piping system itself, an expansion joint is the perfect solution.

An expansion joint is a device primarily formed by flexible bellows used to absorb movements in a piping system while containing pressure and a medium running through it.

The basic advantages to be gained from using Expansion Joints are:

1) Little space required for installation.

2) Absorption of movements in multiple directions due to their inherent flexibility.

3) They require no maintenance.

4) They reduce load and temperature loss to a minimum.

There are three basic movements that can be absorbed by an Expansion Joints: Axial, Lateral and Angular.

| Axial Movement |

Angular Movement |

Lateral movement |

|

|

|

| Axial movement is the change in dimensional length of the bellows from its free length in a direction parallel to its longitudinal axis. |

Angular movement is the rotational displacement of the longitudinal axis of the bellows toward a point of rotation. |

Lateral movement is the relative displacement of one end of the bellows to the other end in a direction perpendicular to its longitudinal axis. |

|

Manufacture and Design

|

|

|

Expansion Joints are designed, manufactured and tested in accordance with:

E.J.M.A. (Expansion Joint Manufacturers Association, Inc.) E.J.M.A. (Expansion Joint Manufacturers Association, Inc.)

Manufacturing Methods

CHEMIQUIP uses different methods for producing the bellows depending upon a range of different contributing factors (eg. diameters, the number of sheets used, the materials used, etc.), although in all cases the bellows are manufactured using seamless tubes or metal cylinders welded along their length. The methods used are as follows: Expanding, Elastomeric, Hydraulic and Roll forming.

Our manufacturing range includes Circular Expansion Joints of the following types:

- Axial

- Hinged

- Gimbal

- Lateral

- Pressure Balanced

- Jacketed

- Externally Pressurized

- Lens

- Flanged & Flued

|

|

|

Quality Control and Testing

|

|

|

Expansion Joints are thought of as high engineering products to which end our Quality Control Department carefully monitors each of the different steps involved in the production process itself, right from the moment the raw materials are purchased up to the final controls and tests carried out on each and every Expansion Joint which come off our production line. All of the quality controls and tests we carry out are based on our Quality Control Manual, approved under ISO 9001, as well as our Quality Procedures.

All of our Expansion Joints undergo a series of controls and tests at each of the different steps in the manufacturing process and before they leave the factory. Every Expansion Joint is submitted to a final Dimensional Check and a Leak Detection Test. The following tests can also be carried out if requested and/or if stipulated in the terms of a contract:

Non-Destructive

- Radiographic Examination

- Liquid Penetrant Examination

- Ultrasonic Examination

- Magnetic Particle Examination

- Pneumatic Pressure Test & Leak Detection Test

- Hydraulic Pressure Test

- PMI (Positive Material Identification)

- Chemical and Mechanical Analysis of materials used

- Spring Rate Test

- Helium Leak Detection Test

|

|

|

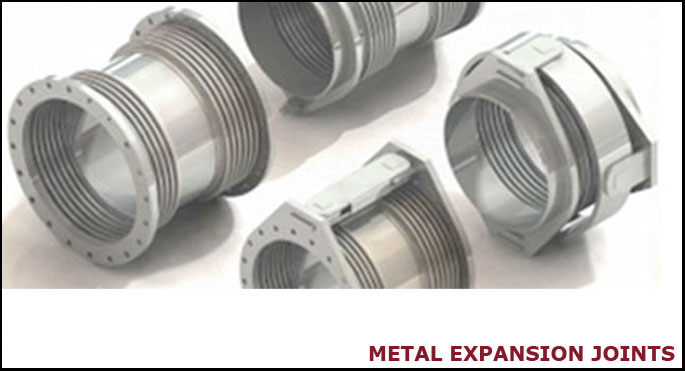

Metallic Expansion Joints Types

|

|

|

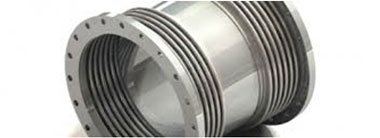

Axial Type:

It is the simplest type of expansion joint. This type of Expansion Joint is made up of one single bellows equipped with fixed flanges. Although this model will in fact absorb all of the movements in any one length of piping it is mainly used to absorb AXIAL MOVEMENTS.

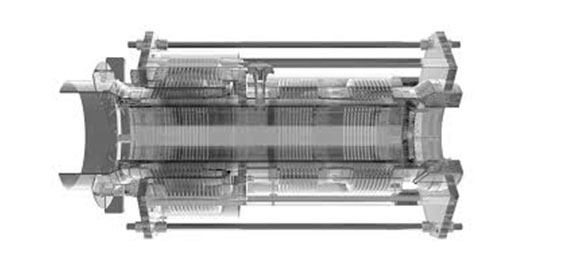

Universal Type:

Also known as the UNIVERSAL UN-TIED EXPANSION JOINT WITH FLANGED ENDS.

This model is made up of two bellows joined together by a central pipe and fitted with flanged ends. Although it can be used to absorb any combination of the three basic movements it is mainly used to absorb large LATERAL MOVEMENTS.

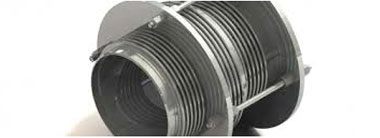

Jacketed Type:

Jacketed Expansion Joints are used in a set of particular circumstances such as when regular insulation is not sufficient and when the main fluid has to be kept at a fixed temperature or simply for security reasons.

This model involves using two bellows, one on the inside and one on the outside.

Elbow Pressure Balanced Type:

ELBOW PRESSURE BALANCED. It is designed to absorb LATERAL AND/OR AXIAL MOVEMENTS ELIMINATING THE THRUST CAUSED BY THE INTERNAL PRESSURE.

In-Line Pressure Balanced:

IN-LINE PRESSURE BALANCED Absorbs Axial and/or Lateral Movements while restraining the pressure thrust. This type of Expansion Joint is used in a straight run of pipe.

Hinged Type:

HINGED EXPANSION JOINT WITH WELDING ENDS. This model is made up of a bellows fitted with welding ends plus a system of articulated supports which allow for ANGULAR MOVEMENTS IN ONE PLANE ONLY.

Gimbal Type:

GIMBAL EXPANSION JOINT. This model is made up of a bellows, provided with welding ends plus two pairs of articulations linked up to a common floating ring. It absorbs ANGULAR MOVEMENTS IN ALL PLANES.

Rectangular Type:

RECTANGULAR EXPANSION JOINT WITH U-SHAPED CONVOLUTIONS AND V SHAPE CONVOLUTION. One or more convolutions for low and medium pressures and full vacuum services. The connection elements are available either with flanges or welding ends.

|

|

|